A Review of Strain Analysis Using Electron Backscatter Diffraction

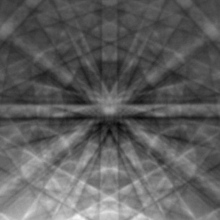

An electron backscatter diffraction blueprint of monocrystalline silicon, taken at twenty kV with a field-emission electron source

Electron backscatter diffraction (EBSD) is a scanning electron microscope–based microstructural-crystallographic label technique commonly used in the study of crystalline or polycrystalline materials.[1] [2] The technique tin provide information nigh the structure,[3] crystal orientation ,[3] phase,[iii] or strain[4] in the cloth.

These types of studies have been carried out using X-ray diffraction (XRD), neutron diffraction and/or electron diffraction in a Manual electron microscope and spatially resolved acoustic spectroscopy (SRAS) which analyses elastic waves instead of analysing a diffraction event. The selection of which technique is adopted depends upon various factors, including spatial resolution, area/volume analysed, and whether the measurements are static or dynamical.

Geometry [edit]

For an EBSD measurement a flat/polished crystalline specimen is placed in the SEM chamber at a highly tilted bending (~seventy° from horizontal) towards the diffraction camera, to increase the contrast in the resultant electron backscatter diffraction pattern. The phosphor screen is located within the specimen chamber of the SEM at an angle of approximately xc° to the pole piece and is coupled to a meaty lens which focuses the paradigm from the phosphor screen onto the CCD camera. In this configuration, some of the electrons which enter the sample backscatter and may escape. As these electrons get out the sample, they may exit at the Bragg status related to the spacing of the periodic atomic lattice planes of the crystalline structure and diffract. These diffracted electrons tin escape the material and some will collide and excite the phosphor causing it to fluoresce.

Inside the SEM, the electron axle is focussed onto the surface of a crystalline sample. The electrons enter the sample and some may backscatter. Escaping electrons may get out near to the Bragg angle and diffract to form Kikuchi bands which correspond to each of the lattice diffracting crystal planes. If the arrangement geometry is well described, it is possible to relate the bands nowadays in the diffraction pattern to the underlying crystal phase and orientation of the cloth within the electron interaction volume. Each band can be indexed individually by the Miller indices of the diffracting airplane which formed it. In nigh materials, but 3 bands/planes which intersect are required to draw a unique solution to the crystal orientation (based upon their interplanar angles) and almost commercial systems utilise look up tables with international crystal data bases to perform indexing. This crystal orientation relates the orientation of each sampled point to a reference crystal orientation.

While this 'geometric' description related to the kinematic solution (using the Bragg condition) is very powerful and useful for orientation and texture analysis, it but describes the geometry of the crystalline lattice and ignores many physical processes involved within the diffracting cloth. To adequately draw effectively features within the electron beam handful pattern (EBSP), one must use a many beam dynamical model (due east.g. the variation in band intensities in an experimental pattern does non fit the kinematic solution related to the structure factor).

EBSD Detectors [edit]

Experimentally EBSD is conducted using a SEM equipped with an EBSD detector containing at least a phosphor screen, compact lens and depression calorie-free CCD camera. Commercially available EBSD systems typically come with 1 of two different CCD cameras: for fast measurements the CCD chip has a native resolution of 640×480 pixels; for slower, and more sensitive measurements, the CCD scrap resolution can go upwardly to 1600×1200 pixels. The biggest reward of the high-resolution detectors is their higher sensitivity and therefore the information inside each diffraction design tin be analysed in more item. For texture and orientation measurements, the diffraction patterns are binned in order to reduce their size and reduce computational times. Modern CCD-based EBSD systems tin index patterns at up to 1800 patterns / 2d. This enables very rapid and rich microstructural maps to be generated. Recently, CMOS detectors have also been used in the blueprint of EBSD systems. The new CMOS-based systems permit pattern indexing faster than CCD-based predecessors. Modernistic CMOS-based EBSD detectors are capable of indexing patterns upwardly to 3000 patterns / second.

Indexing [edit]

Often, the first footstep in the EBSD process after pattern collection is indexing. This allows for identification of the crystal orientation at the single volume of the sample from where the pattern was collected. With EBSD software, pattern bands are typically detected via a mathematical routine using a modified Hough transform, in which every pixel in Hough space denotes a unique line/band in the EBSP. The Hough transform is used to enable ring detection, which are difficult to locate by reckoner in the original EBSP. In one case the band locations have been detected it is possible to relate these locations to the underlying crystal orientation, as angles between bands represent angles betwixt lattice planes. Thus when the position / angles between iii bands are known an orientation solution can exist adamant. In highly symmetric materials, typically more than 3 bands are used to obtain and verify the orientation measurement.

There are two leading methods of indexing performed by nearly commercial EBSD software: triplet voting; and minimising the 'fit' between the experimental pattern and a computationally adamant orientation. A all-time practice guide for reliable information acquisition has been written by Professor Valerie Randle[5]

Triplet voting involves identifying multiple 'triplets' associated with different solutions to the crystal orientation; each crystal orientation determined from each triplet receives ane vote. Should four bands identify the same crystal orientation and so 4 (four choose three) votes will be cast for that particular solution. Thus the candidate orientation with the highest number of votes will exist the most likely solution to the underlying crystal orientation present. The ratio of votes for the solution called as compared to the full number of votes describes the conviction in the underlying solution. Care must be taken in interpreting this 'conviction index' as some pseudo-symmetric orientations may result in low conviction for i candidate solution vs. another.

Minimising the fit involves starting with all possible orientations for a triplet. More bands are included that reduces the number of candidate orientations. As the number of bands increases, the number of possible orientations converge ultimately to ane solution. The 'fit' betwixt the measured orientation and the captured blueprint can be determined.

Pattern center [edit]

In social club to relate the orientation of a crystal, much like in X-ray diffraction, the geometry of the organisation must be known. In particular the pattern center, which describes both the distance of the interaction volume to the detector and the location of the nearest point between the phosphor and the sample on the phosphor screen. Early work used a single crystal of known orientation being inserted into the SEM chamber and a particular characteristic of the EBSP was known to correspond to the pattern centre. Later developments involved exploiting various geometric relationships between the generation of an EBSP and the chamber geometry (shadow casting and phosphor movement).

Unfortunately each of these methods are cumbersome and can be decumbent to some systematic errors for a full general operator. Typically they can not be easily used in modernistic SEMs with multiple designated uses. Thus nigh commercial EBSD systems use the indexing algorithm combined with an iterative movement of both crystal orientation and suggested pattern centre location. Minimising the fit between bands located within experimental patterns and those in look up tables tends to converge on the pattern centre location to an accuracy of ~0.5–1% of the pattern width.

Orientation mapping [edit]

The map in the acquire process.

Contamination on the sample afterward the EBSD mapping.

EBSD tin can be used to discover the crystal orientation of the cloth located within the incident electron beam's interaction volume. Thus past scanning the electron beam in a prescribed style (typically in a foursquare or hexagonal filigree, correcting for the prototype foreshortening due to the sample tilt) results in many rich microstructural maps.

These maps tin can spatially describe the crystal orientation of the cloth being interrogated and can be used to examine microtexture and sample morphology. Some of these maps describe grain orientation, grain purlieus, diffraction pattern (paradigm) quality. Various statistical tools tin can be used to measure the average misorientation, grain size, and crystallographic texture. From this dataset numerous maps, charts and plots can be generated.

From orientation data, a wealth of information can be devised that aids in the understanding of the sample'due south microstructure and processing history. Recent developments include agreement: the prior texture of parent phases at elevated temperature; the storage and rest deformation after mechanical testing; the population of diverse microstructural features, including precipitates and grain boundary character.

Integrated EBSD/EDS mapping [edit]

When simultaneous EDS/EBSD collection tin be accomplished, the capabilities of both techniques can be enhanced. In that location are applications where sample chemistry or phase cannot exist differentiated via EDS solitary because of like limerick; and structure cannot exist solved with EBSD alone because of cryptic structure solutions. To reach integrated mapping, the assay area is scanned and at each point Hough peaks and EDS region-of-interest counts are stored. Positions of phases are determined in X-ray maps and measured EDS intensities are given in charts for each chemical element. For each phase the chemical intensity ranges are gear up to select the grains. All patterns are then re-indexed off-line. The recorded chemistry determines which stage / crystal construction file is used for indexing of each betoken. Each blueprint is indexed past but one phase and maps displaying clearly distinguished phases are generated. The interaction volumes for EDS and EBSD are significantly different (on the gild of micrometers compared to tens of nanometers) and the shape of these volumes using a highly tilted sample may accept implications on algorithms for phase discrimination.

EBSD when used together with other in-SEM techniques such as cathodoluminescence (CL), wavelength dispersive 10-ray spectroscopy (WDS) and/or energy dispersive 10-ray spectroscopy (EDS) can provide a deeper insight into the specimen'due south properties. For example, the minerals calcite (limestone) and aragonite (shell) take the same chemical composition – calcium carbonate (CaCOthree) therefore EDS/WDS cannot tell them apart, but they have dissimilar microcrystalline structures and so EBSD can differentiate betwixt them.

See also [edit]

- Crystallography

- Electron crystallography

- Diffraction

References [edit]

- ^ Randle, Valerie; Engler, Olaf (2000). Introduction to texture analysis: macrotexture, microtexture and orientation mapping (Digital printing 2003 ed.). Boca Raton: CRC Press. ISBN978-9056992248.

- ^ Schwartz, A. J.; Kumar, M.; Adams, B. 50.; Field, D. P. (2000). Electron backscatter diffraction in materials science. New York: Kluwer Bookish.

- ^ a b c Electron backscatter diffraction in materials science (2nd ed.). Springer Scientific discipline+Concern Media. 2009. p. 1. ISBN978-0-387-88135-five.

- ^ Wright, Stuart I.; Matthew, Thou. Nowell; David, P. Field. (2011). "A review of strain analysis using electron backscatter diffraction". Microscopy and Microanalysis. 17. 17 (3): 316–329. Bibcode:2011MiMic..17..316W. doi:10.1017/S1431927611000055. PMID 21418731.

- ^ Randle, Valerie (ane September 2009). "Electron backscatter diffraction: Strategies for reliable data acquisition and processing". Materials Label. 60 (nine): 913–922. doi:10.1016/j.matchar.2009.05.011.

williamshisomed49.blogspot.com

Source: https://en.wikipedia.org/wiki/Electron_backscatter_diffraction

0 Response to "A Review of Strain Analysis Using Electron Backscatter Diffraction"

Post a Comment